CNC Knee Mill - 1050II

Willis CNC Knee Mills - CNC Metalworking Equipment:

- Willis CNC Vertical Mill Machines

- Ranging from:

- > 9" – 11.8" x 49" – 50" Table Sizes

- > 32" – 46" X-Axis Travels

- > 13" – 17" Y-Axis Travels

- > 16" – 18" Knee Travels

- > 3hp & 5hp Spindle Motors

- > R8 & 40 Taper Spindles

- Call us for a free Willis CNC Vertical Mill Machine quote today! - (419) 537-1717

1250II CNC Vertical Knee Mill

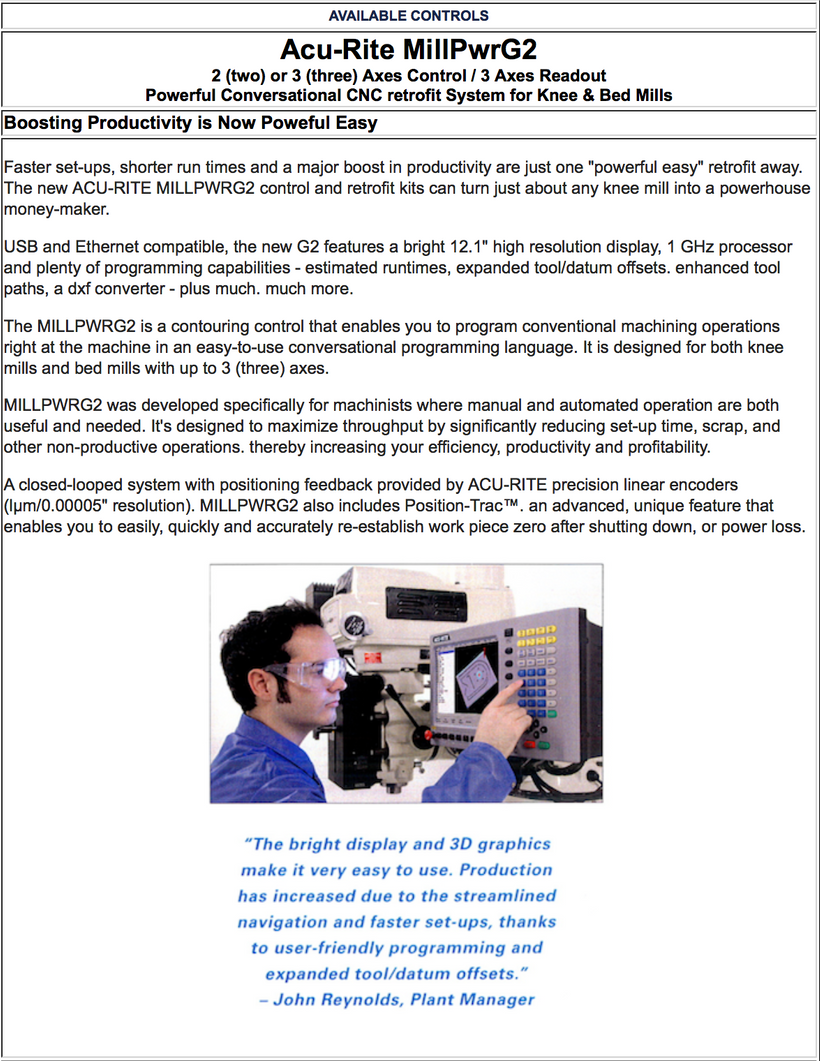

Maintaining all of the standard features accompanied with the Willis conventional knee mills, Willis CNC knee mills also posses ACU-RITE CNC controls with 2 (two) or 3 (three) axis capabilities.

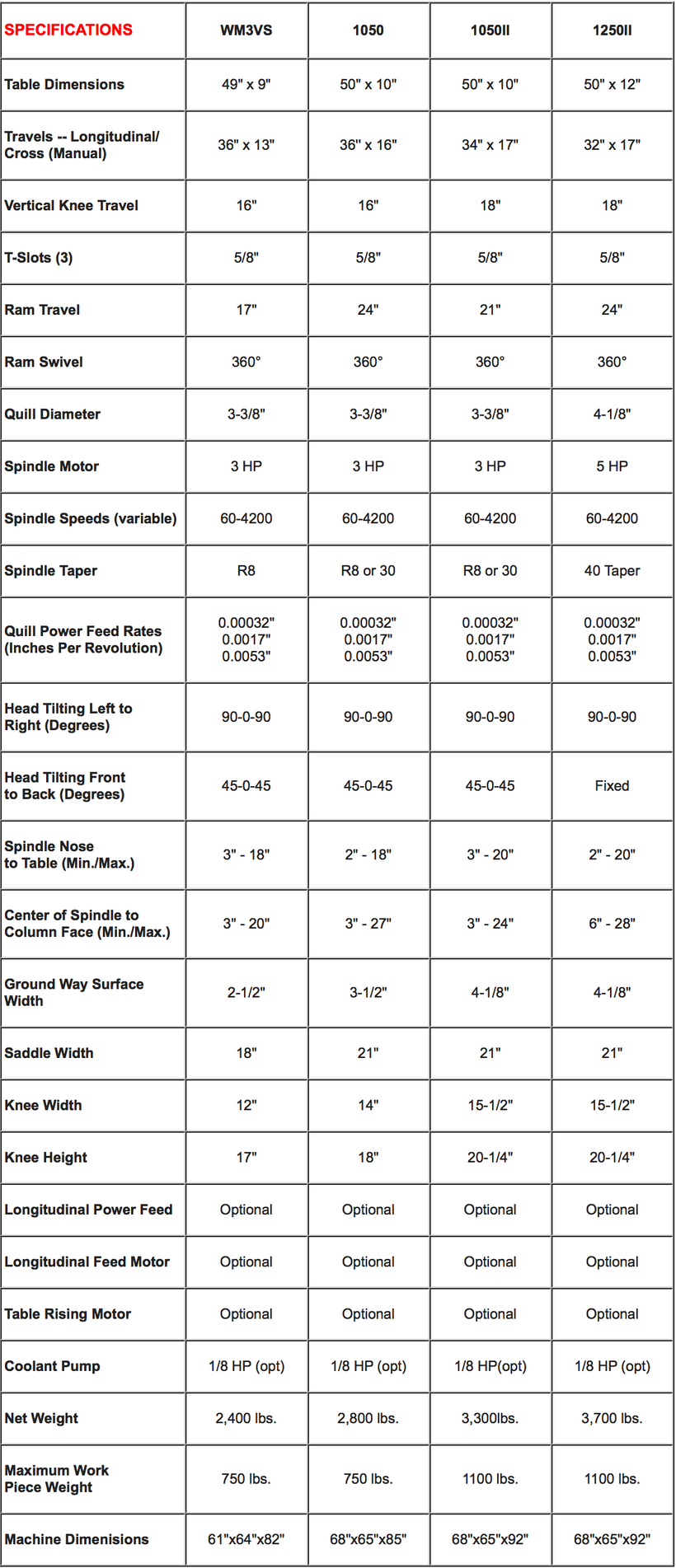

Willis Machinery offers either the "ACU-RITE" MillPWR G2 CNC control on four of its conventional mill machines including the WM3VS, 1050, 1050II, and the 1250II.

Willis CNC knee mills all possess precision ball-screws and nuts on all CNC axes

These CNC vertical mill machines are offered with 2, 3, 3½, or 4-axis controls

A disengageable quill is available on 3 (three) axis CNC knee mill models for manual drilling and tapping

Willis, 2 (two) axis, CNC knee mills are equipped standard with a third axis quill scale digital readout display

Willis CNC Knee Mills offer semi-automatic operations of full 2 (two) or 3 (three) axis CNC operations.

Powerful A/C brushless servo motors provide these CNC mill machines with smooth and accurate positioning

An automatic, metered, lubrication system with low level alarm is standard on Willis CNC knee mills

Optional Servo or Align power knee feed is also available on Willis CNC mill machines

Special Features

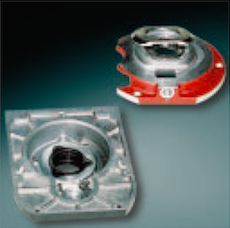

One piece construction is superior to our competitor's 2 piece.

Our design uses a splined pinion shaft which is much stronger and more rigid than the keyed shaft.

Our standard spring type micrometer adjusting nut provides quick and easy movement for setting spindle depth.

Gaskets are used to prevent grease and oil leakage.

One pieces quill housing ensures precise alignment, eliminates vibration, and prevents premature bearing failure.

Dynamically balanced pulley with special bronze key attached with 2 screws prevents premature breakage.

Our special power down feed parts are so strong, they can be used over 3,000 RPM spindle speeds. Our 1 piece cluster gear is superior to the much used 3 piece design.

The splined shaft is much stronger and provides greater safety than the keyed shaft.

Willis 3HP inverter drive milling head - EV.

Inspection

- Spindle Bore Runout.

- less than 0.0004”

- Spindle Running Noise Measuring.

- less than 73 db at 1 meter

- Parallelism of Table Surface to Table Cross Travel Movement.

- less than 0.0008" per 12" of travel

- Squareness of Table Surface to Knee Travel.

- less than 0.0008" per 12" of travel

- Squareness of Table Surface to Quill Travel.

- less than 0.0008" per 5" of quill travel

- Measuring of Squareness of longitudinal Travel to Cross Travel.

- less than 0.0008" per 20" of travel

- Parallelism of Table Surface to Table Longitudinal Movement.

- less than 0.0008" per 20" of travel

- Parallelism of Table Surface to Ram Cross Transverse Movement.

- less than 0.0008" per 12" of travel

Stiffness of Head and Quill Combination.