RTM 100 CNC Bed Mill

RTM100 “Open” CNC Vertical Machining Center

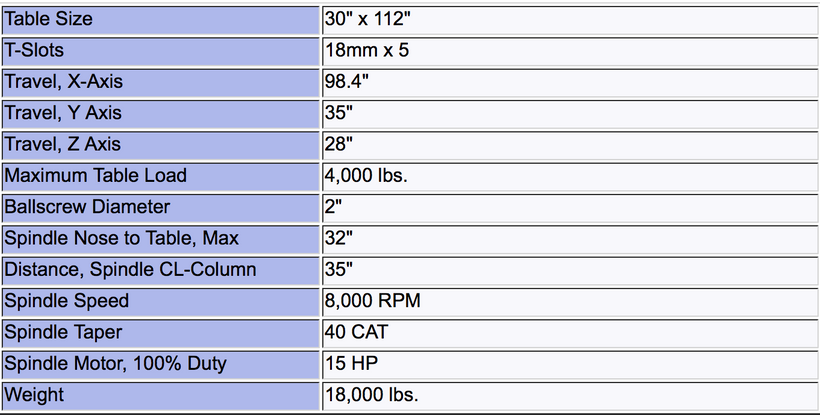

- Specifications:

- Fanuc 0i-MD control AC all digital control

- > 30" x 112" Table Sizes

- > 33" x 100" x 28" Travels

- > Maximum Table Load 4,000 lbs.

- > Up to 8,000 Spindle Speed Programmable

- > 15HP Continuous Duty Spindle Motor

- > Counter balance for milling head

- > 18,000 Machine Weight

- Call us for a free Willis CNC Bed Mill quote today! 419-537-1717

RTM100 “Open” CNC Vertical Machining Center

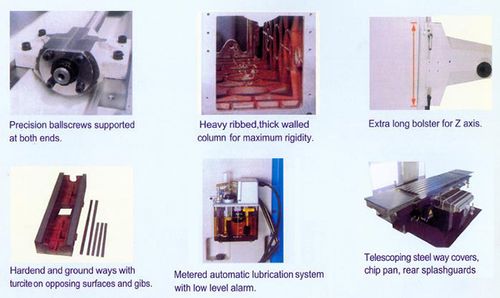

Machine Features:

- Fanuc 0i-MD control AC all digital control

- Fanuc Manual Guide I control software

- 15HP continuous duty Fanuc servo motor for spindle

- All Fanuc AC digital servo motors for each axis

- 100 amps disconnect switch

- RIGID HEAD CAT#40 taper spindle

- Up to 6,000RPM spindle speed

- (24) tools ATC CAT#40

- (24) CAT40 retention knobs

- 30” x 112” working table

- X, Y, Z Travel 98” x 33” x 26” (2500mm x 874mm x 700mm)

- Z-axis brake assembly

- 2-piece column mounted vertical rear splashguards

- Chip / coolant tray for base of machine

- Table mounted splashguard

- Front and rear metal telescopic covers for bed-ways

- Metal telescopic cover for column ways

- Halogen working lamp

- Heat exchanger for electric cabinet

- MPG electronic hand-wheel for manual axis movements

- Auto lubrication pump

- Flood coolant system

- Power Oil Filter

- Heat exchanger for electric cabinet

- Ethernet connectivity

- 3-color alarm light

- Leveling bolts and pads

- All manuals, parts list, and inspection report

Specifications:

Bedmill Features and Optional Accessories:

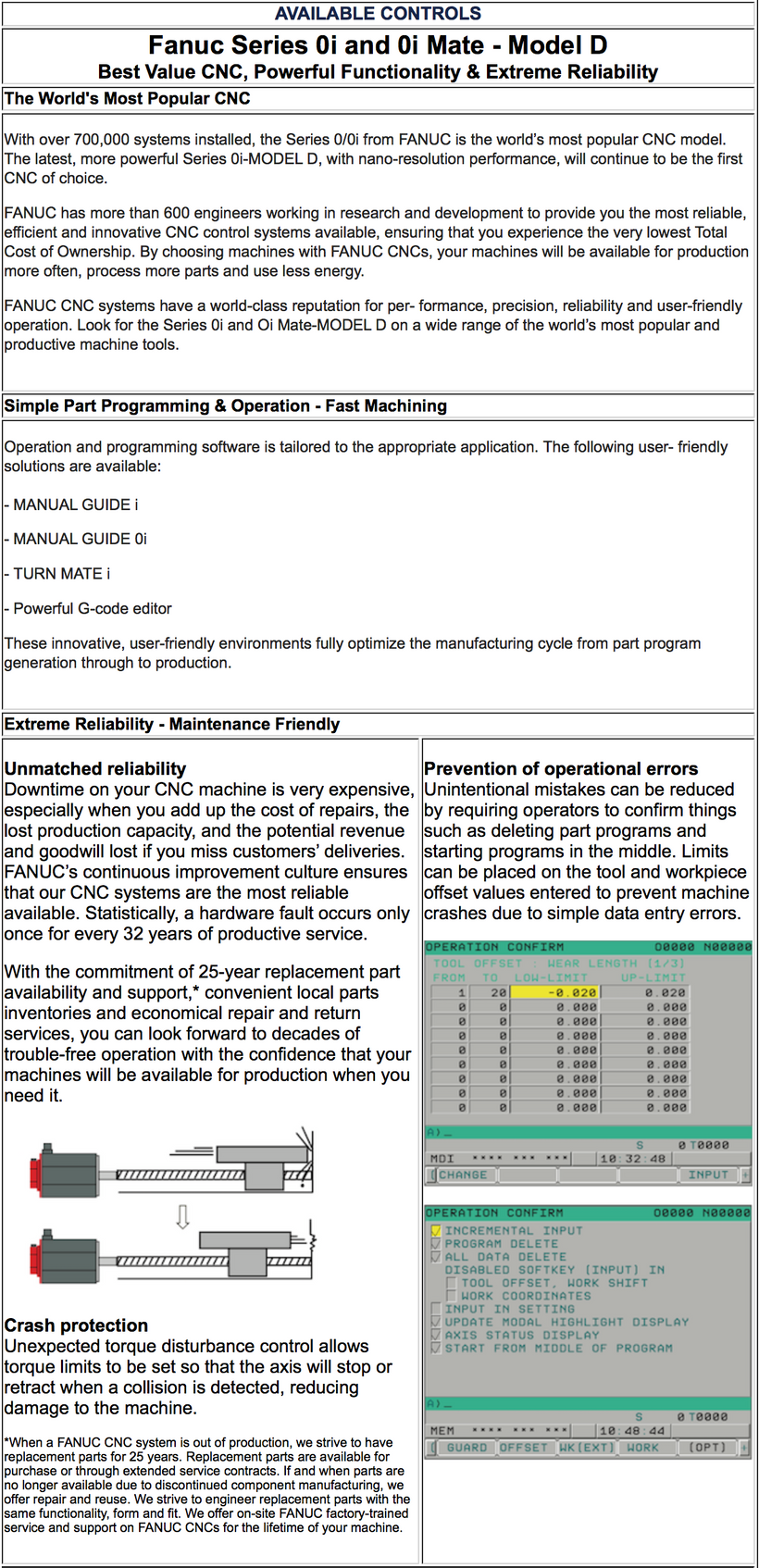

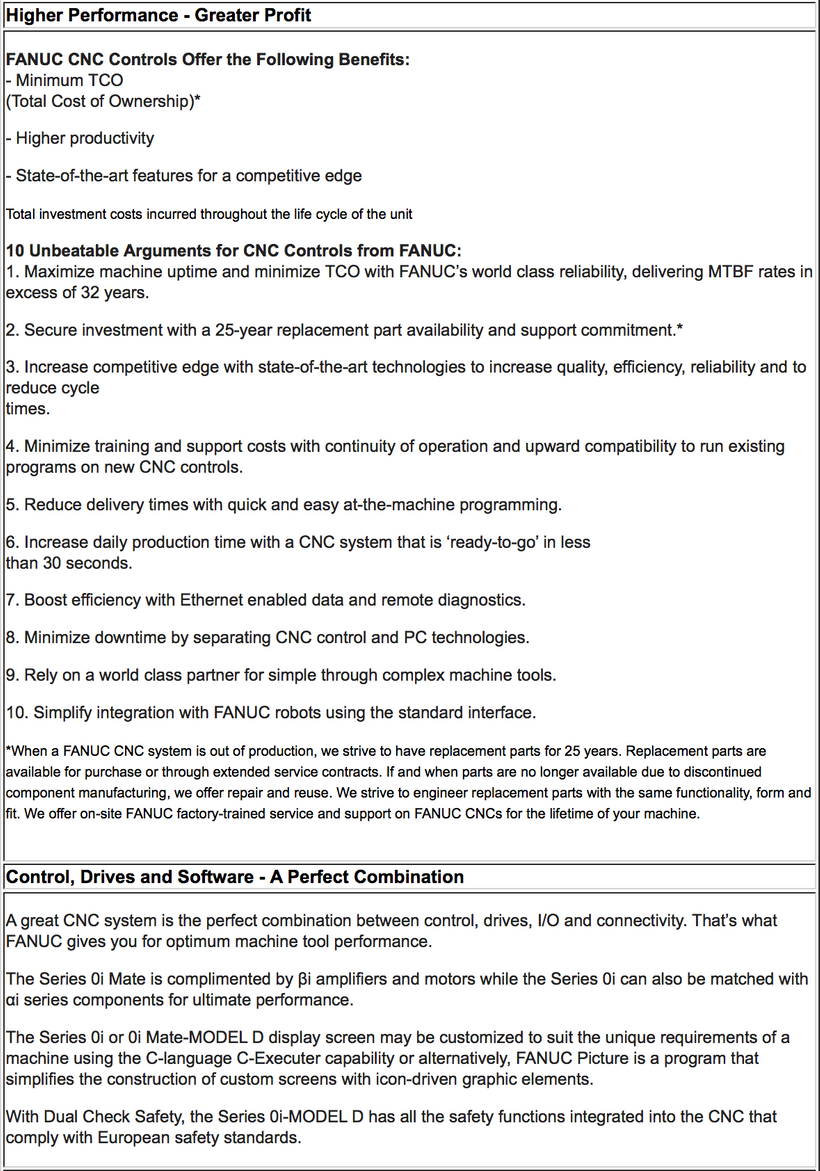

The “Willis” RTM bed mills come standard with the "Fanuc Oi-MDi control, providing three axis or four axis simultaneous controls. These CNC machines are all standard with digital AC controls and drives.

The RTM series CNC bed mills have direct drive spindles. An optional ZF gearbox is available on the RTM series bed mills. The Mills come standard with rigid tapping. The RTM series bed mills are equipped standard with a 20 tool umbrella type automatic tool changer, and optionally available is a 24 tool arm type automatic tool changer. The RTM series CNC bed mills are equipped with an oversize, high precision ball screw on all three axes. The mills are included with an automatic, metered lubrication system with a low level alarm. A flood type coolant system is standard, as are steel telescoping front and rear way covers, a chip pan, and a rear splashguard. A table mounted splash guard is standard on these vertical CNC mills, and a full enclosure is optional.

Fourth axis indexing or full rotary contouring is commonly supplied. X, Y, and Z axis travels range of 100” x-axis x 33” y-axis x 28” z-axis on the RTM 100. Table sizes for the “Willis” RTM series CNC bed mills come as large as 112” x 30” for the RTM 100, which also carries a 4800 lb. table load capacity using a 20HP motor. Digital tool & part probing is available. Optionally offered is “Renishaw”, or other major brands.